Innovate technology and create the future. With technology as the product empowerment, Sunoco is committed to building high-end and international product suppliers

Xinnuo Technology Co., Ltd. has collaborated with multiple domestic universities to create expert workstations, continuously gathering high-level talents and enhancing its independent innovation ability. It has successfully solved the technical problem of 60 years of lockdown in China, achieved independent and controllable core technology, and made positive contributions to enhancing the national strategic scientific and technological strength.

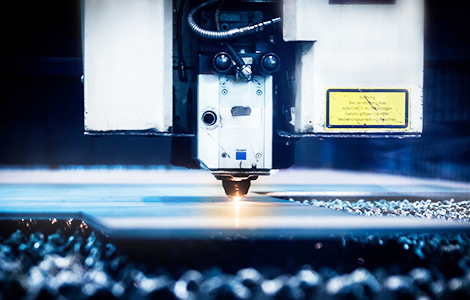

The 3000 square meter R&D and testing comprehensive office building is equipped with complete R&D and testing facilities for the entire precision casting industry chain. The wax is divided into two parts: the precision casting medium temperature wax R&D center and the light alloy precision forming technology center.

At the R&D and Testing Center of Xinnoco Company, researchers have achieved important research results through research and development, completely solving the key technical problems of the 60 year lockdown in China, achieving independent and controllable core technology, 100% localization of raw materials and production equipment, meeting the demand for wax for precision manufacturing of aviation engines in China, and can completely replace similar imported products from abroad. The company has established an excellent research and development team, including 6 people with intermediate and senior professional titles, 6 authorized invention patents, and 31 industrial new model patentsis the main drafting unit for industry standards, national standards, and military industry standards

The China Foundry Association presided over a scientific and technological achievement evaluation meeting, and the comprehensive technical level of the "Research and Application of High Performance Wax Materials for Aerospace Precision Castings" project led by Xinnoco has reached the international advanced level.

The Chinese Aeronautical Society hosted an online scientific and technological achievement appraisal meeting, led by Xinnoco. The comprehensive technology of the "Research and Application of High Performance Wax Materials for Aerospace Engine Precision Castings" project has independent intellectual property rights and reaches the international advanced level.

Provide timely professional consulting services

Service Hotline:400-099-0532

Dispatch professional engineers for on-site inspection

Tailored design solutions for customers

Professional after-sales technical team

24/7 to solve problems during product use for you

Xinnuoke looks forward to sincere cooperation with you!

400-099-0532

400-099-0532

qdsinocast@163.com

qdsinocast@163.com

No.1 Meishan Road, Laixi Economic Development Zone, Qingdao, Shandong Province

No.1 Meishan Road, Laixi Economic Development Zone, Qingdao, Shandong Province

Copyright © 2020-2023 Qingdao Xinnuoke New Materials Technology Development Co., Ltd 鲁ICP备20014294号

Technical support:WDL