It is a non filling wax in the precision casting industry. This type of wax has advanced production technology and can be accurately manufactured within a small range of requirements.

400-099-0532

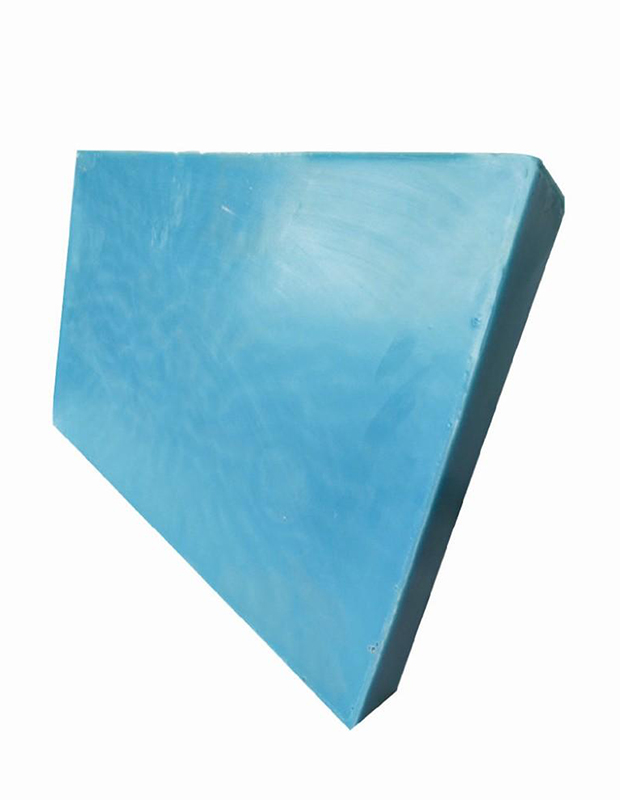

400-099-0532 Golf Head Special Wax

It is a non filling wax in the precision casting industry. This type of wax has advanced production technology and can be accurately manufactured within a small range of requirements.

Features:

Good dimensional stability - It has superior dimensional stability because its linear shrinkage and settlement rates are kept to a minimum.

The high-strength model can maintain its shape even in high-temperature environments, and will not deform during contact, equipment, and polishing processes.

Low grayscale - grayscale below 0.03%, ensuring no contamination of metals.

High productivity - able to accurately reproduce details and have good surface finish.

Easy demolding - demolding is simple and fast.

Application:

Applied to high-end silica sol processes, golf balls, military industries, etc.

Recommended use:

Wax melting temperature: 110 ℃ -120 ℃

Static temperature: 85 ℃ -95 ℃

Insulation temperature: 55 ℃ -65 ℃

Mixing time: ≥ 8 hours

Soaking time: ≥ 12 hours

Insulation time: ≥ 24 hours

Wax injection pressure: 30pa

Typical performance:

Viscosity | cps | IP71 | 800-120 |

Viscosity | cps | IP71 | 200-300 |

Cone penetration | dmm | IP49 | 4-5 |

Softening point | ℃ | IP58 | 75-80 |

Dropping point | ℃ | IP371 | 80-90 |

Freezing point | ℃ | IP76 | 70-75 |

Filler | % | SPL | |

Moisture content | % | SPL | ≤0.15 |

Ash content | % | SPL | ≤0.03 |

Shrinkage rate | % | 0.95-1.2% | |

Bending strength | % | kgf | 4-5 |

Supply form | Granular | ||

Colour | Based on the actual object |

Xinnuoke looks forward to sincere cooperation with you!

400-099-0532

400-099-0532

qdsinocast@163.com

qdsinocast@163.com

No.1 Meishan Road, Laixi Economic Development Zone, Qingdao, Shandong Province

No.1 Meishan Road, Laixi Economic Development Zone, Qingdao, Shandong Province

Copyright © 2020-2023 Qingdao Xinnuoke New Materials Technology Development Co., Ltd 鲁ICP备20014294号

Technical support:WDL