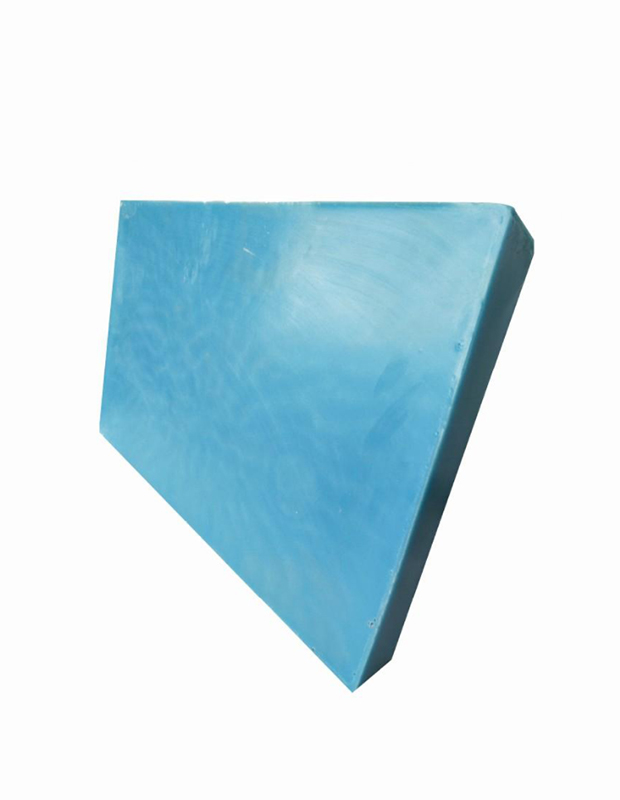

The performance of immersion wax: It is a special wax with low viscosity used to improve surface defects of the gating system. During dewaxing, the immersion wax first melts and is also immersed in the mold shell, providing sufficient space for the expansion of the wax mold and gating system, thereby reducing mold shell cracking during dewaxing. When using, first dissolve this wax at a temperature of 70-85 ℃ and keep it warm, using it like coating.

400-099-0532

400-099-0532 The performance of immersion wax: It is a special wax with low viscosity used to improve surface defects of the gating system. During dewaxing, the immersion wax first melts and is also immersed in the mold shell, providing sufficient space for the expansion of the wax mold and gating system, thereby reducing mold shell cracking during dewaxing. When using, first dissolve this wax at a temperature of 70-85 ℃ and keep it warm, using it like coating.

1. It can significantly improve the wetting and hanging performance of the wax mold on the surface layer coating

2. Defects such as mold shell cracking and slag inclusion caused by sharp corners or slag drop in the pouring system of wax can be prevented

3. Manufactured using special processes, without producing flow marks and wax droplets during use

characteristic

It can significantly improve the wetting and hanging performance of the wax mold on the surface coating. It can prevent defects such as shell cracking and slag inclusion caused by sharp corners or slag drop in the wax pouring system. Manufactured using special techniques, it will not produce flow marks or wax droplets during use.

Softening point: 55-60 ℃

Cone penetration: 7-15

Specific gravity: 0.901-0.922

Wax pressing parameters: 65-95 ℃

Xinnuoke looks forward to sincere cooperation with you!

400-099-0532

400-099-0532

qdsinocast@163.com

qdsinocast@163.com

No.1 Meishan Road, Laixi Economic Development Zone, Qingdao, Shandong Province

No.1 Meishan Road, Laixi Economic Development Zone, Qingdao, Shandong Province

Copyright © 2020-2023 Qingdao Xinnuoke New Materials Technology Development Co., Ltd 鲁ICP备20014294号

Technical support:WDL